Product Description

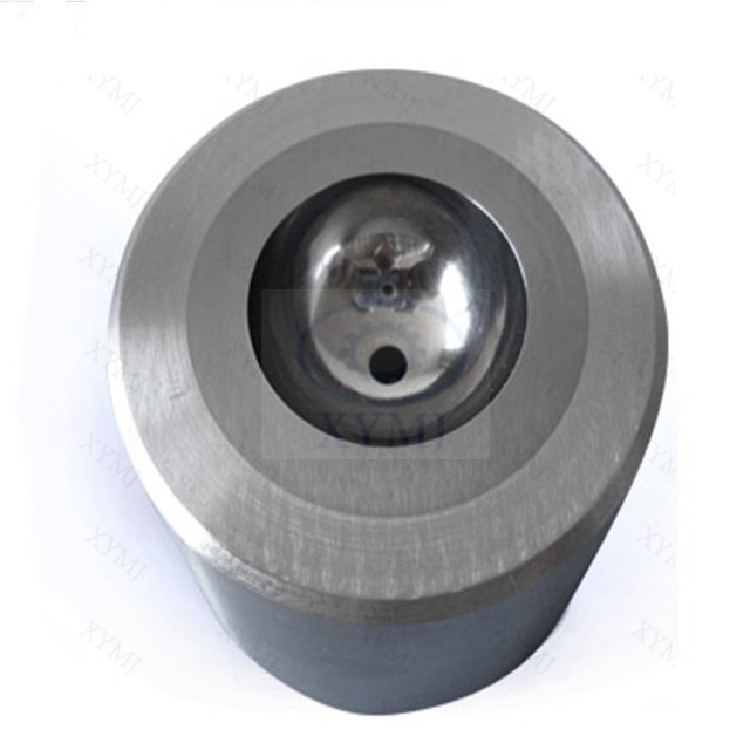

Carbide Wire Drawing Dies are tools used to gradually compress metal wire through the die hole to reduce its cross-sectional area and reach the required size. Compared with other dies, the tungsten carbide materials is applied as the die core of this kind of drawing dies.

Looking back, although the traditional alloy steel die is easy to produce and low in cost, its wear resistance is too poor. This kind of die was gradually eliminated. Although the natural diamond die has excellent physical properties, it is expensive and difficult to process. Therefore, tungsten carbide wire drawing dies came into being.

Wire drawing dies play an important role in the field of metal wire processing and are an important tool for improving production efficiency and product quality. Carbide wire drawing dies have high hardness, excellent wear resistance and thermal conductivity. These features give them longer service life and more precise dimensional control capabilities.

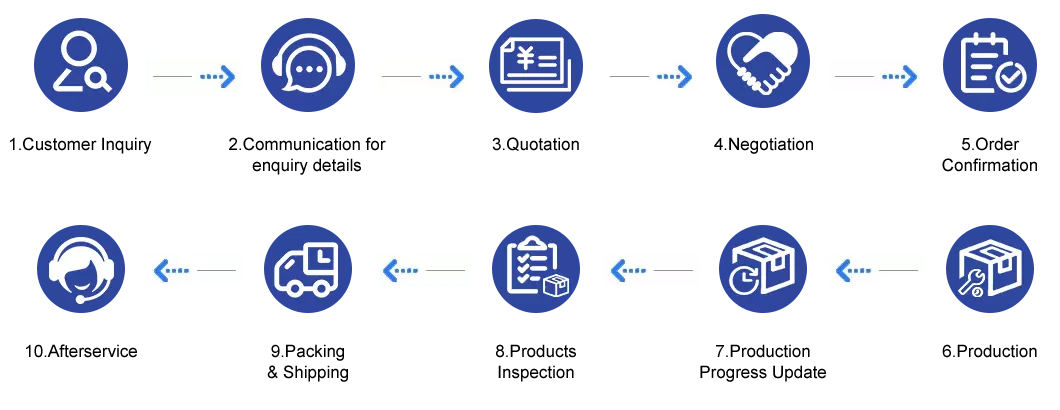

Facing different working conditions and different opponents, the required dies are not the same. Therefore, customization is particularly important. When you send us an inquiry, please attach the complete drawings and other requirements as much as possible.

Specification

- Place of Origin: China;

- Product Name: High Quality Tungsten Carbide Wire Drawing Dies;

- Material: Tungsten Carbide;

- Certifications: ISO9001:2008;

- Grade:YG3X, YG3, YG6X, YG6, YG8, YG15;

- Structure: The entrance area, the lubrication area, the working area, the sizing area, and the exit area;

- Customized Support: OEM&ODM.

Advantages of Carbide Wire Drawing Die:

1. High wear resistance, can be used for a long time. Its service life is not only more than ten times that of steel molds, but also can ensure the dimensional accuracy of the final product;

2. Excellent polishing, the drawn metal products have higher quality;

3. It has low adhesion to the processed metal, and the service life of the mold is greatly improved;

4. The friction coefficient is small, so it can save equipment operating costs during production;

5. High corrosion resistance, it is no problem to contact with lubrication of various properties;

6. As a source factory, we can provide customized production based on 100% virgin raw materials, from material grades to different sizes and shapes, easily adapting to various working conditions.