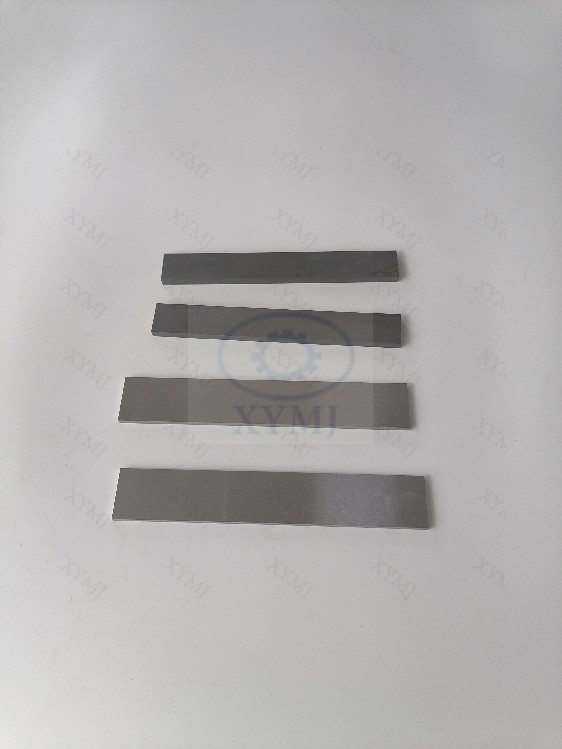

Product Description

Tungsten carbide strips are also known as rectangular tungsten carbide rods, tungsten carbide flats, and tungsten carbide flat bars are sintered metallurgical products of powder form. It is manufactured in vacuum or Hydrogen reduction furnaces with refractory Tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni) as the binder.

Tungsten carbide plate, due to its high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance, remain basically unchanged even at a temperature of 500 ℃, and still have high hardness at 1000 ℃. Therefore, it is widely used in machinery. The physical properties of hard alloys are at least three times that of steel. It can be made into various hard alloy plates, hard alloy rods, hard alloy nozzles, tungsten carbide seals, wear and tear, etc.

Tungsten carbide plates are widely used in the electronics industry, motor rotors, stators, LED lead frames, EI silicon steel sheets, etc. All hard alloy blocks must be inspected strictly and only those without any damage, such as pores, bubbles, cracks, etc., can be shipped out.

Specification

- Material: Cemented Carbide

- Shape: Rectangular

- Origin: China

- Surface: Sintered and finishing machining

- HS Code: 82090010

- Production capacity: 20ton per month

- Certificate: ISO9001

- Hardness:89.5-91HRA

- Brand: XYMJ

- Specification: customized made

- Application: Woodworking tools, such as forming tool, reamer, serrated knife blade and various blade

Characteristics of Tungsten Carbide Plate:

- Excellent thermal stability and high-temperature deformation resistance.

- The mechanical temperature is high at high temperatures.

- Good thermal shock resistance.

- High thermal conductivity.

- Excellent oxidation control ability.

- Corrosion resistance at high temperatures.

- Excellent corrosion resistance to chemicals.

- High wear resistance.

- Long service life.

Application:

Tungsten carbide plates have excellent longitudinal hardness, high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation), low impact toughness, low coefficient of expansion, and heat-resistant conductivity similar to iron and its alloys. Silicon steel sheets and cold-rolled plates are suitable for making stamping parts and deep drawing dies, wear-resistant parts, and mold cores for automatic hard alloy presses. They have good strength and impact toughness, but lower wear resistance than the above-mentioned alloys. Used for high load top forging dies, such as those for screws, rivets, etc., and also for stamping dies. Squeezing mold. Punching dies, etc

Why Choose Us?

- 26 years tungsten carbide products production experience since 1999

- High precision inspection equipment and advanced carbide blank production line to ensure tungsten carbide plate and strip products.

- High precision production equipment and auto grinding machines to make sure the sizes.

- Advanced technology process and precise grinding.

- Professional engineer team and experience workers

- Competitive quotation, stable quality, fast delivery

FAQ:

Q1: How many work experience for tungsten carbide rod and plate?

A1: Since 1999.

Q2: Can you provide samples?

A2: Yes, we can , as long as customer send us drawing.

Q3: Why you have advantage for tungsten carbide plate and strips?

A3: We can work mould by ourselves to press the plate and strips, and high precison grinding equipment and QC control.

Q4: Can you provide different material grade?

A4: Yes,We can work different material grade in our workshop.

Q5: How to control your carbide strip and plate quality?

A5: high precision inspection equipment and excellent QC and engineer team.