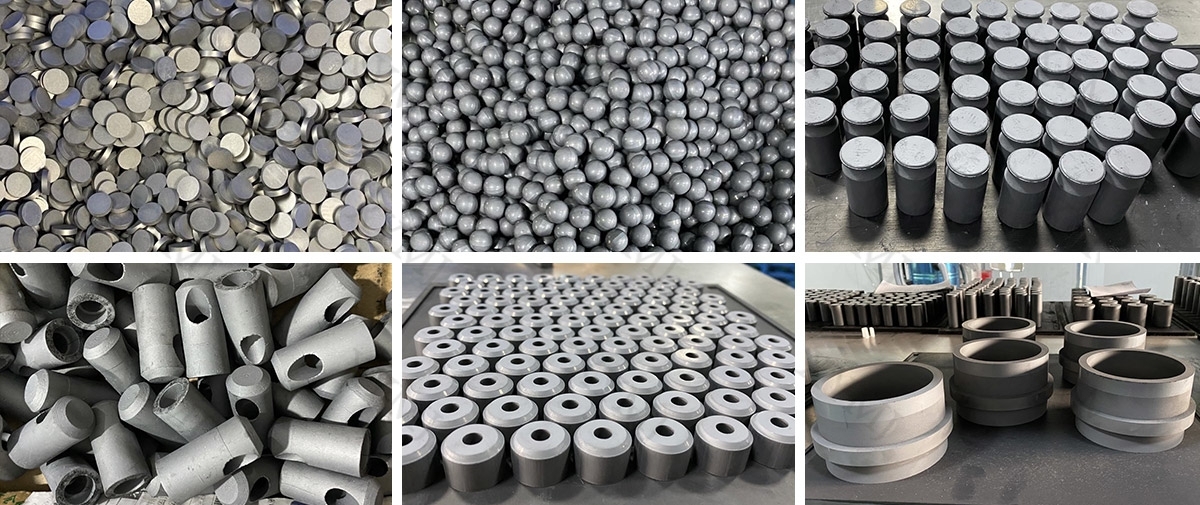

Product Description

Tungsten carbide blank is a formed blank made of composite material, which is mainly composed of tungsten carbide particles combined with metal (cobalt or nickel). Manufacturing various high-precision tools and components starts from tungsten carbide blanks.

They are produced through processes such as mixing, pressing, sintering, and semi processing to ensure their strength and structural integrity required for various applications.

Tungsten carbide blanks are widely used in industries such as petroleum and natural gas, automotive, mining, manufacturing, beverages and aerosols, construction, medical, etc.

Tungsten carbide blanks are mainly composed of tungsten carbide (WC) particles and metal binders, usually cobalt (Co). Among them, tungsten carbide (WC): High hardness and wear resistance make prefabricated components suitable for high stress applications.

Cobalt (Co): Adhesive enhances the toughness and overall structural integrity of prefabricated components.

Metal elements such as nickel or titanium can also be added to improve specific properties such as corrosion resistance or thermal stability. The ratio of tungsten carbide to binder metal can be adjusted to achieve specific properties required by customers.

The production process of tungsten carbide cobalt (YG) alloy.

Mix tungsten carbide and cobalt in the desired ratio, then add alcohol to form balls

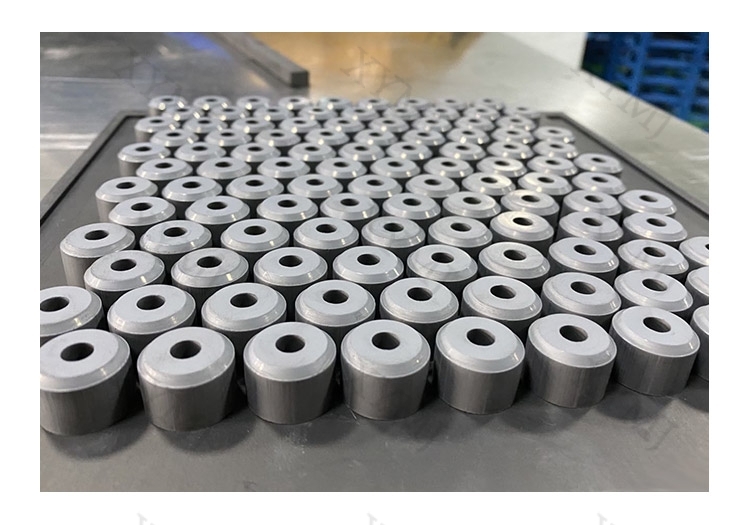

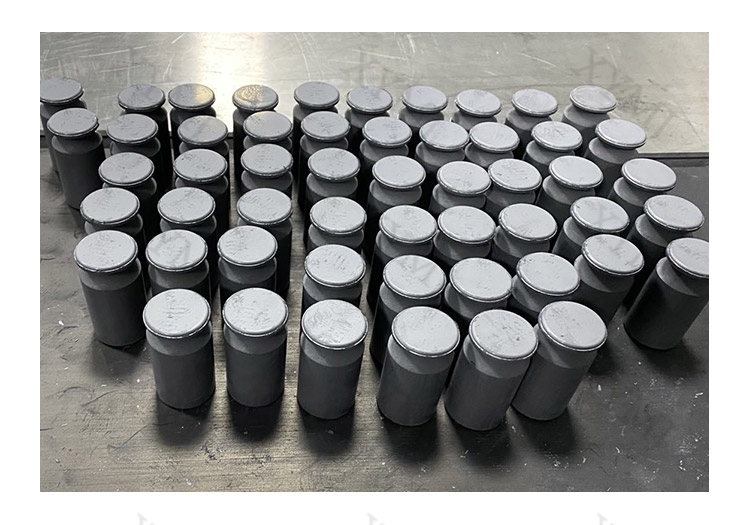

Grinding. After ball milling, it is dried, sieved, and a forming agent is added. Then, it is dried, scraped, and sieved Obtain the required tungsten cobalt alloy mixture. The mixture is sent for compression molding (if automatic pressure is used).

During machine pressing, the mixture also needs to be granulated. The formed billet is dried or dewaxed, pre fired, and processed After inspection, it is loaded into a hydrogen protected sintering furnace or vacuum furnace for sintering, cooled and discharged from the furnace,After sandblasting cleaning and inspection, the final product is obtained.

Grade Recommended

The grades which used more frequently are YG6, YG6X,YG8, YG10,YG10X YG15, YG20, YG25, YN8, YN10 etc.

Other grades can be offered according to customers’ requirements.

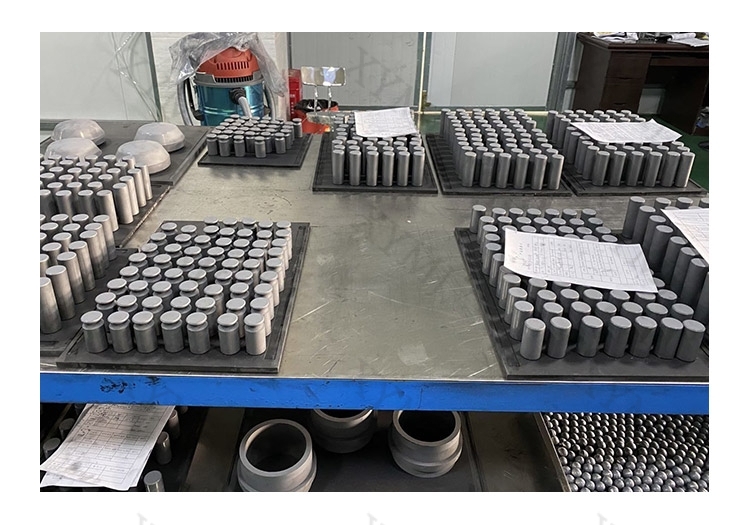

Capacity

We have sophisticated equipment, such as Sintering Furnace, Automatic suppress Machine, Manual Hydraulic Suppress Machine, Ball Mill Machine, Drying Machine, Mixing Machine etc, Our production capacity up to 10 Ton per month. Customized is welcome,customized sample can be ready in 3-5 days .

Quality control:

- All raw materials are tested in terms of density, hardness and TRA and HV30 before use

- Every piece of product goes through in-process and final inspection

- Every batch of product can be traced

Advantage

- Superior heat stability.

- Anti-deformation in high temperature.

- Fine thermal shock resistance.

- High thermal conductivity.

- Excellent Oxidation control ability.

- Strong anti-corrosion in high temperature.

- Good corrosion resistance from Chemical.

- High-wearing feature.

- Long usage lifetime.

Why choose us ?

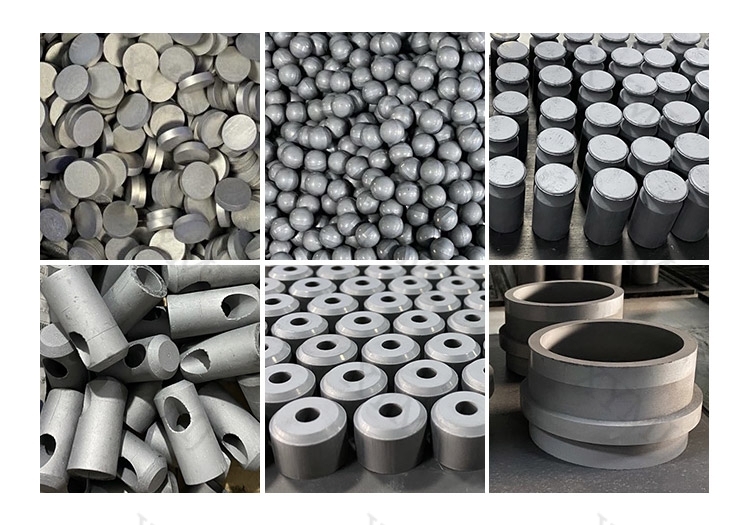

- We have completed carbide blank workshop production line, therefore we can work many kinds of different shape carbide blank according to customers drawings.

- Customers can get different material grades from our carbide blank workshop .

- Advanced inspection equipment to ensure high quality carbide blank.

- High wear resistance, high hardness and impact toughness

- Advanced carbide blank production process Technologies

- ISO quality control and stable and reliable.

- Competitive quotation and fast delivery time , excellent engineer team and experience workers.

FAQ:

Q1: You have carbide blank production line?

A1: We have carbide blank workshop , we can work many kinds of carbide blank by ourselves , and also work different material grade .

Q2: How can you produce the carbide blank?

A2: We mixed tungsten carbide power , pressing and sintering.

Q3: Can you support customized made?

A3: Yes,we can produce them totally according to customer’ drawing, we also can produce mould by ourselves , we use our mould to press carbide blank.

Q4: Can you provide different material grades?

A4: Yes,our carbide blank workshop can provide different material grade for cusotmers’ different require.

Q5: How to make sure products quality?

A5: We can provide all production process quality control.